Creation process

Am Anfang einer Leo Prinz Natural Hair Brush steht immer die Auswahl des perfekten Holzstücks. Hierbei achten wir besonders darauf, in schon bestehenden Hölzern geeignete Stücke zu finden, um Abfall zu reduzieren und weniger neue Bäume fällen zu müssen. Ein Teil kommt aus dem Recycling von kleinen Möbelstücken, Accessoire-Gegenständen und Werkzeugen. Solche Stücke haben aufgrund ihres Alters und der Lagerung eine hohe Qualität und schöne Maserungen. Beim Ahorn Kebony Holz kommt danach noch ein Bio Veredelungsprozess hinzu, der das Holz weniger anfällig gegen Nässe macht und ihm eine dichtere Haptik verleiht.

Als Nächstes beginnt die grobe Bearbeitung. Aus einem massiven Holzstück wird nun der einzigartige Bürstenkörper herausgeholt. Im weiteren Schritt werden die feinen Kanten mit Spezialwerkzeugen gefräst. Am Ende folgt der Feinschliff. Dieser kann zum Teil nur von Spezialisten von Hand erfolgen.

Nach gründlicher Reinigung werden die Bürstenkörper in mehreren Schichten sorgfältig lackiert und getrocknet. Durch diesen Veredelungsprozess wird die Bürstenoberfläche glatt und versiegelt. Dies führt zu einem erheblich besseren Schutz gegen Feuchtigkeit, was die Bürste für Ihren Einsatz in Umgebungen wie etwa dem Badezimmer ideal vorbereitet.

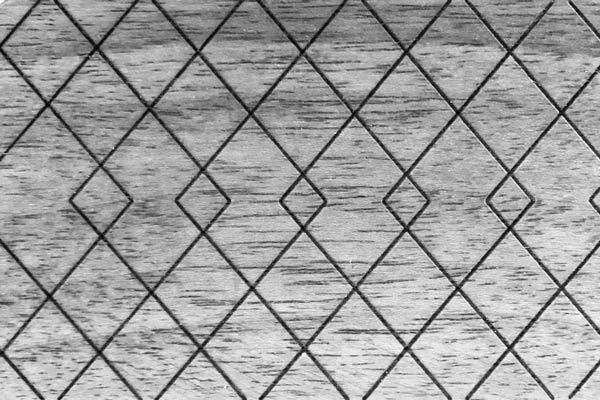

Mit einem Präzisionslaser werden die individuellen Leo Prinz Muster in den Bürstenkörper graviert.

Die individuellen Muster sorgen für das einzigartige Leo Prinz Design und stehen zudem für verschiedene Strukturen, die sich auch in den Haartypen wiederfinden.

Aus dem Holzgriff und den hochwertigen Wildschweinborsten entsteht jetzt eine echte Leo Prinz Wildschweinborstenbürste. Dazu werden, je nach Bürstenmodell unterschiedlich viele, Löcher in den Bürstenkörper gefräst. Im Anschluss wird jedes zuvor fein säuberlich sortierte Borstenbündel einzeln verankert. Dieser Prozess findet bei den Professional (Handeingezogenen) Modellen komplett von Hand statt. Er kann nur noch von wenigen Spezialisten mit jahrelanger Ausbildung durchgeführt werden. Hier werden sogar die dafür benötigten Werkzeuge speziell von Hand gefertigt. Der Materialeinsatz ist minimal und die Borsten bekommen die gleiche Ausrichtung wie die Holzform, welche der Kopfform nachempfunden wurde.

Im nächsten Schritt kommt der individuell passende Vollendungsprozess. Das Borstenfeld wird entweder auf Geradlinigkeit oder auf Effilierung hin überprüft. Die Imperfektion in der Effilierung kann auf den ersten Blick als fehlerhaft erscheinen. Die Funktion dahinter ist allerdings eine gewünschte Ungleichmäßigkeit, die mit individueller Vielfalt im Haar besser umgehen kann.

Überstehende Borsten werden abgeschnitten und auf Fehler überprüft. Danach kommen sie in die Verpackung und werden direkt zu euch geschickt.